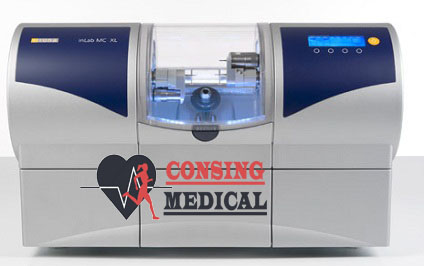

Sale – Sirona Cerec InLab MCXL Milling Unit

The inLab MC XL milling and grinding unit opens up the widest possible range of production options for your dental laboratory. You profit from high speed and precision. You can switch from grinding to milling in just a few simple steps. And thanks to the large milling volume and broad spectrum of applications, you will reap substantial economic benefits.

inLab MC XL

Large range of materials:

Processing of zirconium oxide, resin, silicate ceramics and NP-metal

High-speed milling:

For example, a four-unit zirconium oxide bridge can be completed in just 40 minutes

Large milling capacity: For restorations consisting of up to 12 units and ceramic blocks measuring 85 x 40 x 22 mm

Four milling motors: Flexible selection of milling burs for different materials

Milling and grinding: For high precision regardless of the materialand indication

Milling* of zirconium oxide and polymers

In addition to grinding, you can also mill zirconium oxide and polymers on the inLab MC XL. You benefit from an enhanced initial fit and a faster production process.

Cost-effective production

The inLab software positions your zirconium oxide restorations optimally in the material block – for efficient use of blocks, attractive unit prices and the best possible machine utilization, e.g. by milling or grinding overnight.

Wet grinding of sintered NPM blocks

“inLab goes metal.” With the inLab MC XL and the new inCoris CC sintered metal blocks you can handle a complete spectrum of metal and ceramic materials. The unique wet grinding function rules out any health risks.

Reviews

There are no reviews yet.